GlassWalk™ Structural Glass Floors

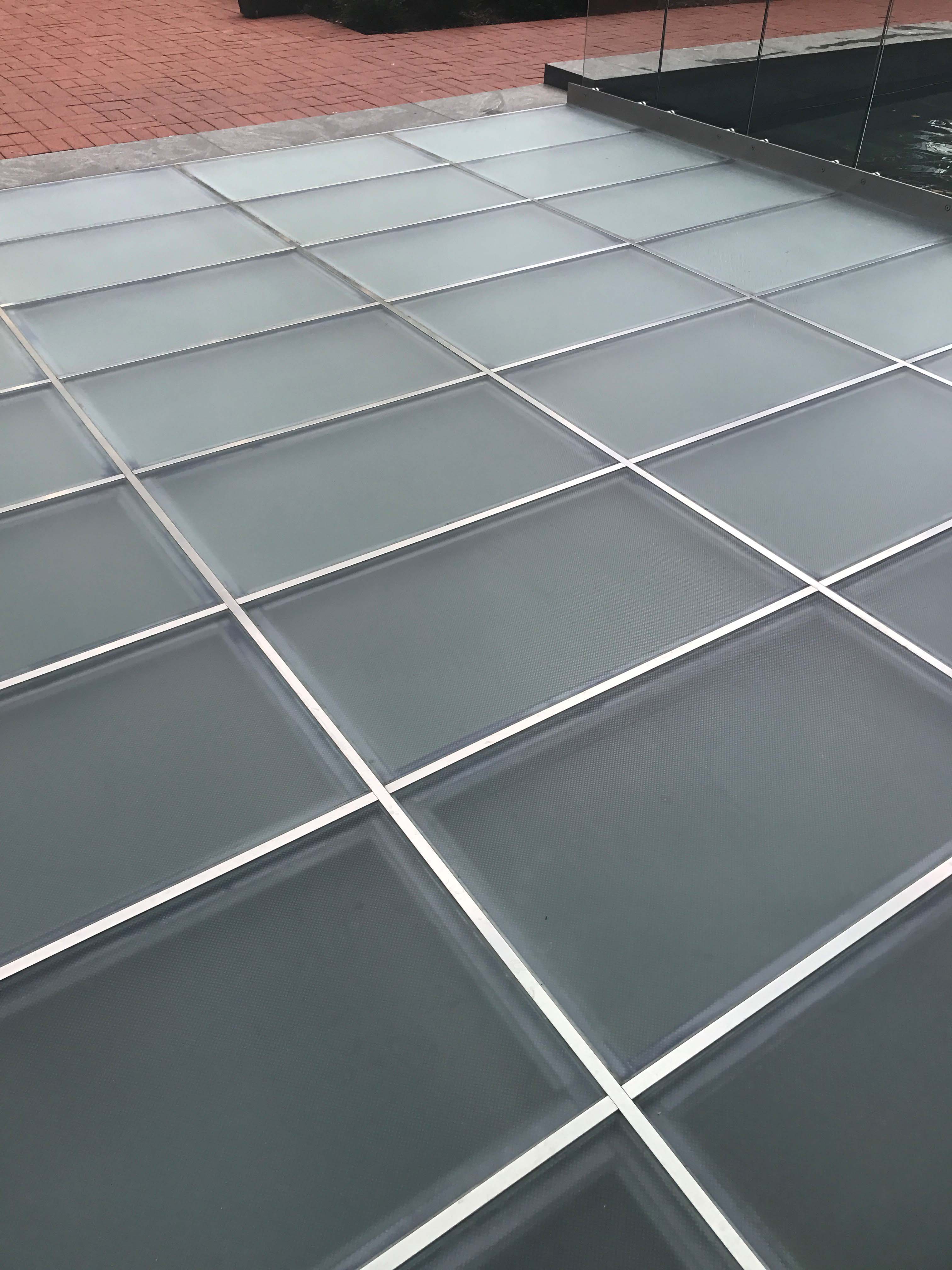

Glass floor panels like our GlassWalk™ Structural Glass Floors create an unforgettable experience, making every step feel as if you're walking on air. These stunning panels can be customized with colors or team logos between the glass layers for a bold, personalized touch. Whether translucent or transparent, they deliver dramatic visual impact in both commercial and residential spaces. Designed for ease of installation and tailored to your vision, GlassWalk™ Structural Glass Flooring turns your dream space into a breathtaking reality.

Utilize Glass Flooring To Enhance Your Space

Introducing the GlassWalk™ Structural Glass Floor System, a visually striking and innovative solution for modern architectural spaces. This structural glass flooring not only enhances the aesthetics of your interiors but also maximizes natural light, creating a bright and open environment.

The GlassWalk ™ system stands out with its exceptional engineering, rigorously tested for durability and safety. Its flexible design allows seamless integration into a variety of projects, making it an ideal choice for architects and builders. Elevate your space with a sleek, transparent floor that merges beauty with cutting-edge performance.

Add a Stunning Design Feature with a Walkable Glass Floor

We're the leader in glass floors and glass panels from concept through final installation

What Customers Say

"We could not be happier with your product and services. We relied on you quite a bit to set the coordination of several items – ceiling heights, curb construction, detailing/engineering – and can’t imagine having another vendor without your expertise and patience. Jeff was especially great throughout the entire experience.

100% will recommend you all here for any other projects in our office.

" — Neal Harrod, Rockwell Group

"I saw the final glass block wall in person and it really is a work of art. We are so grateful for your team’s hard work on this." – Crister Cantrell, Gensler

"Work was done very professionally with outstanding quality. Your crews were very attentive to detail & made sure to protect surrounding work surfaces from damage. They communicated well with my field team to ensure we & the Owner were satisfied with the end product. Job well done." - Russell Stafford, RNGD A Palmisano Company

"We were lucky to have GBA on our project at Lutheran East High School. From the front office to the field supervision and crew were very knowledgeable with our project. Took extra care not to damage the building during demolition. The quality of materials and their labor force was top-notch." — Peter Powell, Carey Construction Group

"We are extremely pleased with the outcome of the glass block at Lutheran East High School and have received many compliments on the design. The glass block windows give the building a nice “pop” of color on the exterior each side of the gym and helped to maintain the identity of the school." - Rick Jozity, Meraki Architects, L.L.C

"As the Senior Project Manager for the general contracting company responsible for completing all aspects of the historical restoration, structural rehabilitation, and adaptive reuse modifications to the derelict Triboro tuberculosis hospital, one of the most difficult challenges was finding capable and qualified subcontractors for the key restoration trades that are both committed to quality construction and respectful of the historical restoration process. I am lucky enough to have worked with GBA on previous successful projects and was glad to bring them into this project. GBA provided the essential expertise and quality craftsmanship that this project needed and was a reliable partner helping us convert the Triboro Tuberculosis Hospital into the T Building Residence." – Senior Project Manager, Bill Harwood for the GC, Mega Contracting

"On behalf of me, my project manager and CGC; I would like to reach out to applaud the quality and workmanship of the crew sent out to do the glass block wall outside of the theater here in Hudson. Dan and Nate went above and beyond to keep their work area organized and clean, even protected our finish trim and VWC in the mixing area with plastic. If only more companies active on site would follow in your companies steps these buildings would be cut and dry and run very efficiently. Thank you! - Jake M. Behler, Cameron General Contractors

Historic Glass Floor Applications

GBA is the perfect partner in any historic renovation project, ranging from glass block to structural glass floors. The presence of historic features probably means that you've purchased a building that may require conservation when it comes to renovations. Thankfully, a glass floor can satisfy any legal obligations while ensuring the renovated space looks beautiful. Glass floor systems are the perfect product to display centuries of history below your feet while protecting the space for years to come. Not only does this preserve important history, but it creates a point of interest that guests will remember.

Structural glass floor panels over historic railroad tracks at Main Street Station in Richmond, VA.

Common Applications

Fire rated glass floor

Fire-rated glass floors provide a unique blend of safety and aesthetic appeal, allowing natural light to penetrate through levels while still adhering to strict fire safety regulations. These systems are engineered to resist fire for specified durations, making them an innovative solution for creating transparent spaces without compromising on structural integrity and fire protection.

Glass floors in houses

Glass floors in houses create a stunning visual impact by allowing light to flow between levels, enhancing the sense of space and modernity. These floors are not only aesthetically pleasing but also engineered to meet safety standards, making them a practical yet luxurious addition to contemporary home designs.

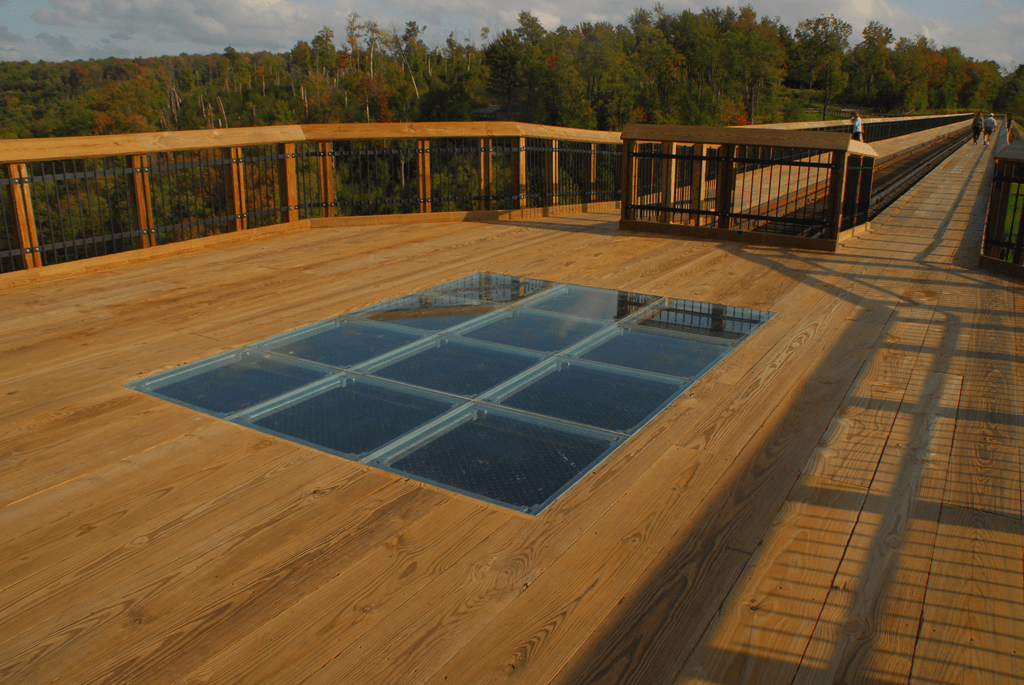

Glass deck

A glass deck provides a sleek, modern outdoor space that maximizes views and natural light while maintaining safety and durability. Designed with high-strength glass panels, these decks offer a unique, transparent flooring option that seamlessly blends with the surrounding environment.

Glass deck flooring

Glass deck flooring is designed to withstand various weather conditions, combining durability with a unique, transparent aesthetic that enhances any deck.

Glass balconies

Glass balconies provide a modern and open feel to any building, enhancing views and natural light while maintaining safety through the use of durable, transparent flooring. These balconies blend seamlessly with architectural designs, offering a sophisticated and visually appealing outdoor space.

Glass skylights

Glass skylights introduce abundant natural light into spaces while offering the unique feature of being walkable, seamlessly blending functionality with modern design.

Glass floor installation

Glass floor installation requires precise engineering and expert craftsmanship to ensure both safety and aesthetic appeal and our team is the right choice.

Glass stairs

Glass stairs provide a sleek and contemporary look, transforming any space with their transparent elegance while maintaining strength and safety.

Floating glass stairs

Floating glass stairs create a striking visual effect by appearing to hover in mid-air, offering a modern and minimalist design element that enhances the openness of any space.

Glass pavers

Glass pavers offer a durable and visually stunning solution for outdoor spaces, combining the strength of traditional pavers with the unique, light-enhancing properties of glass.

Cast iron and glass pavers

Cast iron panels with glass pavers, or sidewalk vault lights , are used to provide natural light to underground areas that typically receive poor lighting. Cast iron vault light panels are pre-fabricated to meet today’s structural loading requirements. While this feature dates back to the mid-1800s we have modernized it through our engineering and design expertise. Our vault lights are strong enough to be walkable but they also maximize light flow through panels. Additionally, cast iron and glass paver sidewalk lights can illuminate the streets at night when the panels are backlit. Do not think that pulling a design feature from the Victorian era is too much of a throwback. Our vault lights expand on the original concept and modernize vault lights for the 21st century.

Steel and glass pavers

Steel and glass paver applications incorporate the use of 6” or 8” square glass pavers. Glass pavers can be clear or sandblasted on the top surface. The framework to this walkable glass floor paver application is made from standard steel, stainless-steel, or hot dipped galvanized steel for added strength. The steel framework can be finished in a powder coat that comes in a variety of colors. This is perfect for any application that is interior/exterior since it can be waterproofed.

Precast concrete and glass pavers

Precast concrete and glass paver panels are fully engineered and tested to meet structural loading requirements. Glass pavers are offered in many standard paver sizes, and GBA offers historic pavers for historic preservation projects. Glass pavers are glazed to be clear or sand blasted for added slip resistance on the top surface. The concrete is available in 6 standard color options and can have an Acid Etched, Light Broom, or Sand Blast finish. Precast concrete panels with glass pavers are designed to be used in an interior/interior, exterior/exterior, or interior/exterior application.

Vault lights

Vault lights not only enhance safety and visibility but also add a distinctive, vintage charm to modern urban designs.

Common Applications

- + Access Flooring

- + Glass Floor Balcony

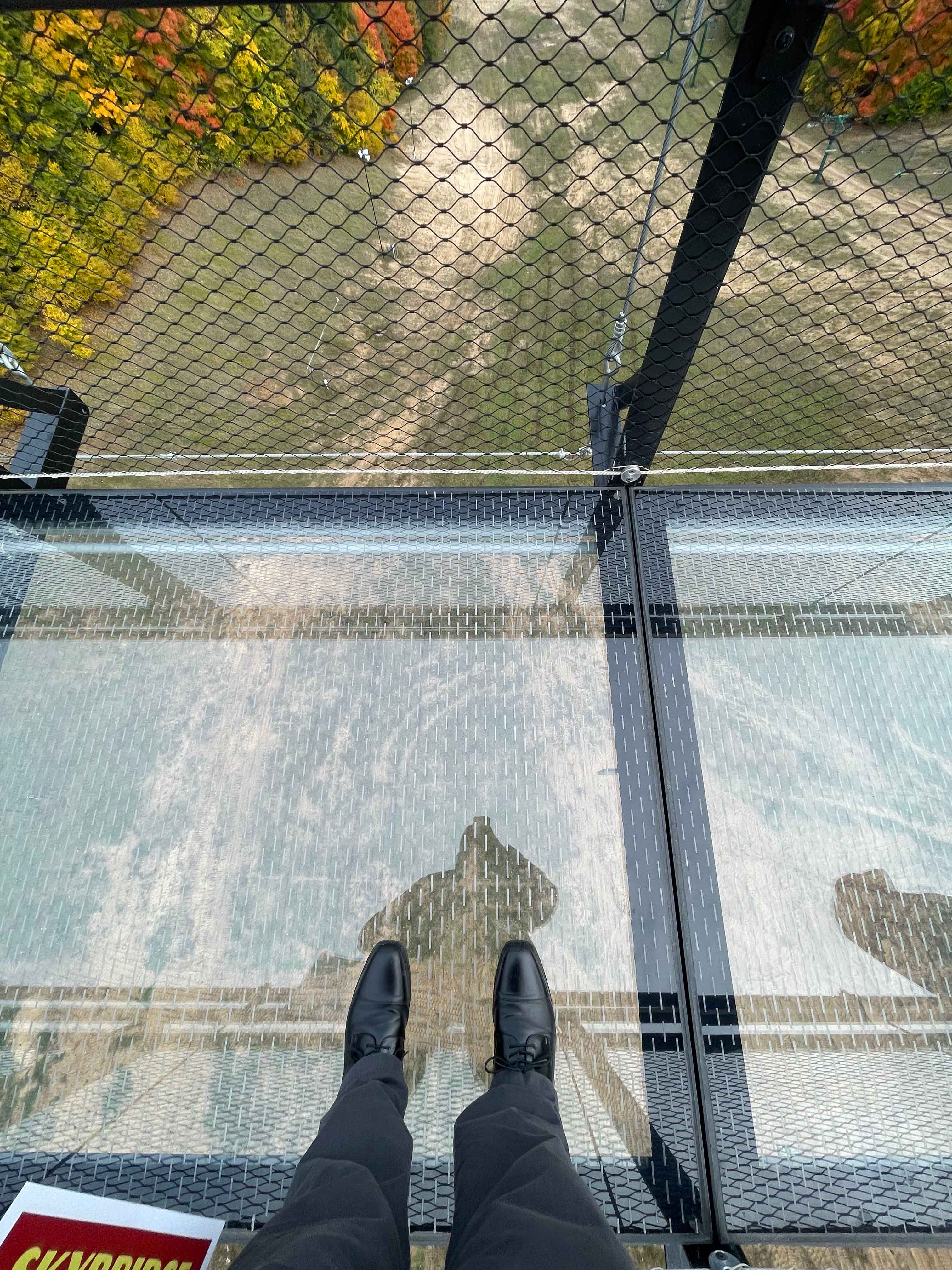

- + Glass Bridges

- + Catwalks

- + Glass Deck

- + Display Floors

- + Glass House Floor

- + Lobby Floors

- + Glass Floor Loft

- + Glass Floor Skylight

- + Stair Landings

- + Wine Cellars

Add a Stunning Design Feature with a Walkable Glass Bridge

We're the leader in glass floors and glass panels from concept through final installation

Structural Glass Floor Design

- Standard glass (green/blue hue) or low-iron glass for a crystal-clear look

- Fully transparent, fully translucent, or anything in between

- Slip Resistant Options

- Traction control ceramic frits, acid etched Walker Textures, or sandblasting offer excellent anti-slip qualities and is perfect for wet or dry conditions

- Clear or Colored Interlayers are available to add a splash of color to your project

- Digital Printing or Silk Screening can be applied to your glass panel to provide a unique feature to your project

- Custom shapes and sizes available

- 2 or 3-ply laminated glass units

One major concern of the glass floors is the level of privacy a person walking on the glass has. By acid-etching the glass or changing the transparency of the glass, you can create the desired level of privacy for those walking on your glass floor. Despite changing the transparency or adding additional frit patterns, the natural light pouring through the glass will not change.

Architectural Grade Aluminum Grid System

- 6063-T6 aluminum is both light weight and super strong

- Framework finishes come in a clear anodized, matte silver finish

- Framework can also be powder coated to match any color to meet your project's color scheme

- Designed to match any custom shaped glass floor

- Aluminum structural members have up to 25% post-consumer recycled content

GlassWalk™ Series 2000 Glass Floor

Glass Thickness: 0.935"

Glass Makeup:- 3/8" tempered glass

- .060 (PVB/SGP) interlayer

- 1/2" tempered glass

Maximum Span: 48" without intermediate support

Glass Options:

- Low Iron or Standard Glass

- Transparent (see-through) or Translucent (obscure)

- With or without Traction Control Frit

Framework:

- 6063-T6 aluminum grid frame

- Standard semi-gloss black or white powder coat finish

- Frame depth: 4-1/16"

Cushion: Clear silicone cushion

Glass Weight: Approx. 13 lbs per square foot

Grid Weight:

- Perimeter: Approx. 1.5 lbs per lineal foot

- Spanner: Approx. 2.5 lbs per lineal foot

.png?width=1080&height=1080&name=ig%20glass%20floor%20(1).png)

Series 2000 Technical Details

Series 2000 Training Course

The GlassWalk Series 2000 is our most cost-effective system, built with 2-ply glass designed to handle live loads of at least 100 lbs per square foot. This ensures the floor safely distributes weight over time. For instance, a 200-lb person standing typically spreads their weight across multiple square feet, keeping pressure within safe limits.

GlassWalk™ Series 3000 Glass Floor

Glass Thickness: 1.245"

Glass Makeup:- 3/8" tempered glass

- .060 (PVB/SGP) interlayer

- 3/8" tempered glass

- .060 (PVB/SGP) interlayer

- 3/8" tempered glass

Maximum Span: 88"

Glass Options:

- Low Iron or Standard Glass

- Transparent (see-through) or Translucent (obscure)

- With or without Traction Control Frit

Framework:

- 6063-T6 extruded aluminum

- Semi-gloss black or white powder coat finish

- Custom welded with predrilled holes

- Frame depth: 4-1/16"

Cushion: Clear silicone cushion

Glass Weight: Approx. 18 lbs per square foot

Grid Weight: Approx. 2.0 lbs per lineal foot

Series 3000 Technical Details

The GlassWalk Series 3000 delivers strength, safety, and design flexibility. It supports wide spans, offers multiple glass and finish options, and ensures long-term durability with watertight sealing.

GlassWalk™ Series 4000 Glass Floor

Glass Thickness: 1.245"

Glass Makeup:- 3/8" tempered glass

- .060 (PVB/SGP) interlayer

- 3/8" tempered glass

- .060 (PVB/SGP) interlayer

- 3/8" tempered glass

Maximum Span: 88"

Glass Options:

- Low Iron or Standard Glass

- Transparent (see-through) or Translucent (obscure)

- With or without Traction Control Frit

Framework:

- Custom-welded A36 Carbon Steel frame

- Overall depth customizable to project needs

Cushion: Clear silicone cushion

Glass Weight: Approx. 18 lbs per square foot

Grid Weight: Varies by application

Installation Options: Face-mount or flange-mount installation

Series 4000 Technical Details

The GlassWalk Series 4000 features a strong, multi-layered glass panel built for high durability. Its custom-welded steel frame supports curved or irregular openings and is available in standard or custom-finish options, offering both structural integrity and visual appeal.

- Fully engineered and tested to meet a live load of 125 lbs. PSF

- Stamped engineered drawings are available for all 50 states and Canada

GBA encourages the use of an engineered glass floor system like our GlassWalk™ floor system. We design the glass to fit flush within your desired opening, to withstand live load requirements, and be structurally sound to ensure the safety of glass flooring panels. Adding your own glass panels found elsewhere and not approved by our design team can create an unsafe walking area. GBA provides design assistance and engineered drawings when required to ensure an easy installation of the glass floor panels. The aluminum grid, spanning members, and glass panels will be shipped to you and designed to fit into your opening.

Glass Flooring Installation

Before installing your glass floor system, it is important to thoroughly read all directions, construction details, and provided drawings. Wear gloves and use caution when installing the any of the metal framework that has sharp edges. Avoid any rough treatment, dropping, and scratching of the framework during the assembly of the aluminum. Most importantly, when installing your glass floor system, refer to your approved shop drawings for the required opening dimensions and the glass floor dimensions.

Each structural glass floor is shipped as a complete kit to simplify the installation process. GlassWalk™ systems are designed to be set in a safe, supported opening to support the weight of the floor while also holding live loads as required by building codes. All of the elements provided to you will be precut to the exact project specifications.

.png?width=446&height=270&name=Rectangle%2030%20(1).png)

In certain applications, GBA can produce high load structural glass floors that can handle the weight of cars, trucks, or any other vehicle.

GlassWalk™ glass flooring systems are easy to install. When installing a structural glass floor, precut silicone cushions are set on each side of the grid opening prior to placing the glass panels. Once the perimeter is in place, it is time to install the spanners as needed, per project specifications, followed by the structural glass floor panels. Our glass flooring system is designed to be set in an opening that has a containment ledge to support the typical self-weight of 14.3 psf.

The GBA Advantage in Structural Glass Flooring

When it comes to integrating walkable transparency into architectural design, GBA Architectural Products + Services leads with expertise and innovation. Our GlassWalk Structural Glass Floor systems are engineered for strength, beauty, and lasting performance — offering an elegant solution for both natural light transmission and modern design impact.

Whether you're building a statement piece for a commercial entryway, illuminating a lower level with walkable skylights, or enhancing a contemporary residence, our structural glass floor systems are tailored to meet your vision and structural requirements. With a range of slip-resistant finishes, framing systems, and glass configurations, we work closely with architects and builders to create installations that are as safe as they are stunning. We also offer popular pavement lights, a beautiful way to put lights underfoot in outdoor applications.

Discover how our decades of experience and commitment to quality can support your next design. To explore the possibilities for your project, contact us today.

Midwest: 877-280-7700

East Coast: 212-255-5787

West Coast:213-634-7050

Glass Floor FAQs

What kind of glass is used for flooring?

Tempered laminated glass serves as the perfect choice for creating stunning and secure glass floors.

What is the lifespan of glass flooring?

With proper care and maintenance, glass floors have the potential to endure for several decades.

What are examples of structural glass?

We have successfully completed various projects that showcase the excellence of our structural glass work, such as the stunning Main Street Station in Richmond, Virginia..jpg?width=600&height=846&name=Main%20Street%20Station%20(15).jpg)

Is structural glass expensive?

While structural glass floors can often be pricey, we pride ourselves on providing the most budget-friendly options for your glass flooring needs.

What is the definition of structural glass?

Structural glass encompasses a wide range of glass types that bear a portion of the structural weight. In the context of our system, structural glass specifically pertains to the glass panels utilized as floors or walking surfaces.

How strong is structural glass?

Our structural glass is meticulously engineered to not only meet but surpass a 100 pound live load requirement.

Can you walk on glass floor?

Glass floors are commonly used in architectural and interior design to create unique visual effects. To be strong enough to support the weight of people and objects, they are typically made from specially designed and reinforced glass.

The ability to walk on a glass floor safely depends on factors such as the thickness and makeup of the glass, the support structure beneath the glass, and the weight-bearing capacity of the floor. Many glass floors are designed to meet safety standards and can support the weight of people without any issues. However, it's essential to ensure that the glass is properly installed and maintained to prevent accidents or breaking.

High-quality walkable glass is tempered, 2- or 3-ply laminated glass with a live load capacity of 125 lbs PSF.

Where are glass floors used?

Glass floors are used in various architectural and design applications to create unique and visually stunning effects. Some common places where glass floors are used include:

- Museums and art galleries: Glass floors can be found in some museums and art galleries, often used to showcase exhibits or artifacts below the floor. This allows visitors to view items from different angles and perspectives.

- Observation decks: Many observation decks in tall buildings or tourist attractions use glass floors to provide a thrilling experience for visitors. Walking on a glass floor high above the ground offers a unique and exciting perspective.

- Bridges and walkways: Some pedestrian bridges and walkways incorporate glass floors, offering pedestrians a view of the area below, such as rivers, canyons, or natural landscapes.

- Residential and commercial buildings: Glass floors are sometimes used in residential or commercial spaces for aesthetic reasons. They can add a sense of openness, light, and modernity to the design. In homes, glass floors may be used in specific areas like staircases or as part of a design feature.

- Aquariums: In aquariums and underwater observatories, glass floors are used to create the illusion of walking on the ocean floor while observing marine life below.

- Retail spaces: Glass floors are used in some retail stores to showcase products or provide a unique shopping experience.

- Restaurants and bars: Some restaurants and bars incorporate glass floors, often with views of cellars or aquariums below, adding an interesting element to the dining or entertainment experience.

- Historic sites: Some historic buildings with architectural significance use glass floors to allow visitors to view archaeological excavations or preserved structures beneath the floor.

- Luxury resorts and hotels: Glass floors are sometimes featured in high-end resorts and hotels, particularly in overwater bungalows or suites where guests can view marine life directly under their accommodations.

Cleaning the Structural Glass Floors

Routine cleaning is an important part of maintaining the beauty of your glass floor, especially when the glass is used in an exterior application such as a glass deck. Deposits left on outdoor glass balconies can corrode the glass and permanently stain the surface. To wash an exterior glass floor, first rinse the glass with water to remove any dirt. Once the glass is soaked, use an abrasive free detergent and soft brush to wipe the glass. We advise using a squeegee to dry the glass, or a cloth to dry any water around the gasket, frame, or sealant.

The same non-abrasive cleaning practice should be used for your interior glass floor as well. When drying your glass floor inside, it is best to dry with a soft towel before using a squeegee to remove any water streaks in the glass. If anything remains on the glass floor after cleaning it, you can combine water and isopropyl alcohol in a 50/50 solution. Using this solution and a moderate amount of pressure should eliminate any hard-to-remove contaminants on your structural glass floor. If you intend to vacuum dust and dirt particles, be sure the bottom surface of the vacuum is smooth and will not scratch the top layer of your glass panels. A non-hard bristled broom is recommended to sweep any debris from the glass floor panels.

Cleaning the Aluminum Grid Framework

To clean the grid of your interior structural glass system, a soft cloth with water will typically be enough. The clear anodized finish on the GBA grid system will resist airborne dirt. For any stain that cannot be removed by water, we recommended using a mild detergent on the surface. Be sure not to rub the grid vigorously as it can create an undesirable glossy area over the satin finish. Use a rag, sponge, or soft bristled brush with a moderate to light amount of force depending on the stain. Never use abrasive, solvent-type cleaners or paint remover as they may dull or remove the finish.

Caring for an exterior application of this GlassWalk™ system can be tricky. First, note that the exterior clear anodized aluminum framework will turn a natural gray overtime. Once the entire grid has turned gray, it is difficult to bring back the original finish of the grid. The responsible party should decide if the goal is to have a soft natural gray appearance to the grid, or if the design intent is to keep the aluminum finish bright and looking new. For a natural gray appearance, relax and let nature do the job for you, as the natural gray will develop over time. If you intend to keep the silver finish bright, lacquering and waxing the grid before any weather begins can preserve the grid's beauty. When it comes to selecting a wax and lacquer, any wax free of abrasives and cleaners can be used to clean the grid. Automotive lacquers in a spray-can may be used on the grid and can provide longer protection. Never use varnish or shellac on your grid unless directed by the manufacturer.

Glass Floor Frequently Asked Questions

Are there other names for glass floors?

The official name of our glass floor application is GlassWalk™ Structural Glass Floor Systems. Customers often refer to this as the following: structural glass, glass flooring, walkable skylights, floor glass, deck glass, and glass flooring systems.

How thick does a glass floor need to be?

The typical GlassWalk glass floor can be 1” or 1 ¼” thick based on the options for glass which are offered. GBA offers two structural glass options for the glass flooring: 2-Ply (1”) and 3-Ply (1 ¼”). Both structural glass options are available in standard glass or in low iron glass, with several traction control frit patterns available as well.

What is the best glass for floors?

The best and most popular glass flooring option tends to be the low iron glass option with any traction control frit pattern. Low iron glass provides customers with a crystal-clear look allowing you to see through the glass.

How strong is structural glass?

Our glass floors are designed for a 100 pound per square foot live load. Most residential homes are designed for only a 40- or 60-pound live load.

What is the most popular installation application of glass flooring?

The most popular installation applications for glass flooring systems is to lay the glass over an area that is showcased (i.e. wine cellar, historic artifacts), as an exterior skylight, or as an exterior deck. Walkable glass exterior skylights allow large amounts of natural light to the area below. Additionally, when used in a deck application, the glass will bring light under the deck, into windows, or to a lower level.

How easy is it to install a glass floor?

GlassWalk glass floor systems are designed for an easy install. GBA will provide detailed installation instructions, drawings, and details to aide with the installation of our GlassWalk Structural Glass Floor Systems.

What type of glass floor can you walk on?

When incorporating a glass floor system into any project, it is important to make sure that the glass is safe to walk on. GlassWalk™ Structural Glass Floor systems are designed and engineered to meet 100 lbs. psf live load.

Can you scratch a glass floor system?

Yes, structural glass floors can scratch. Depending on the depth of the scratch, you may be able to buff it out.

Is a glass floor installed in metal or concrete?

The glass floor panels are installed by being set into a metal framework. Glass flooring is capable of being installed flush with any existing floor. GlassWalk can be installed into any existing metal or concrete floor.

.jpg?width=1024&name=structural-glass-floors-barn-pa%20(8).jpg)

.jpg?width=480&name=loft%20in%20DC%20(7).jpg)

.jpg?width=1024&name=structural-glass-floors-barn-pa%20(6).jpg)

.jpg?width=5152&name=600%20Mass%20(3).jpg)

.jpg?width=1024&name=structural-glass-floors-barn-pa%20(2).jpg)

.jpg?width=1024&name=structural-glass-floors-barn-pa%20(1).jpg)

-1.jpg?width=3968&name=BGSU%20Mosaic%20Work%20(8)-1.jpg)